Mochini o chitjaNa haholo-holo mochini oa phepelo ea lichatn, mochine o lerata le mochine oa phetiso, mochini o fokang oa motlakase, karolo ea motlakase le lisebelisoa tse ling.

1. Mochine oa ho fepa

Mokhoa oa ho fepa ka yorn o boetse o bitsoa mochine oa ho fepa ka oa ho fepa ka yarn, o kenyeletsang seretse, aE-ba Feeder ea Yarn, le aTataiso ea Yarnle brakete ea litlolo.

Litlhokahalo tsa mochine oa ho fepa ka oplanism:

.

.

(3) tekanyo ea ho fepa yarn pakeng tsa sistimi e 'ngoe le e' ngoe e tlisoang ke eona. Palo ea phepelo ea yarn e lokela ho ba e ka fetoloang ho fihlela litlhoko tsa lihlahisoa tsa ho fetola

.

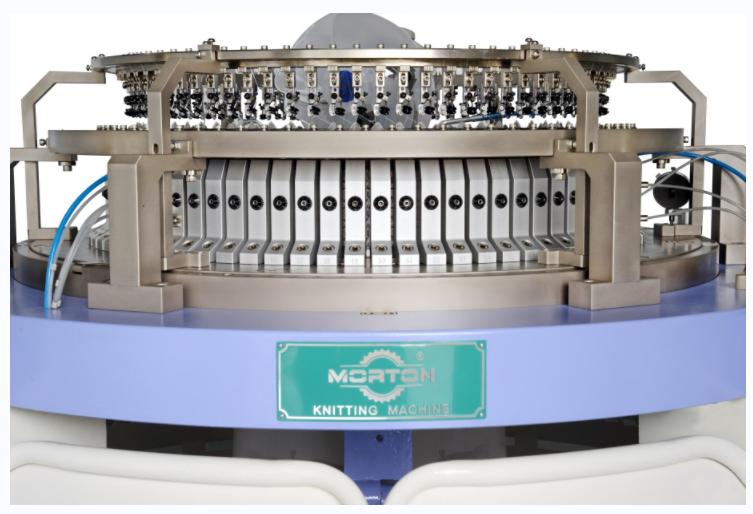

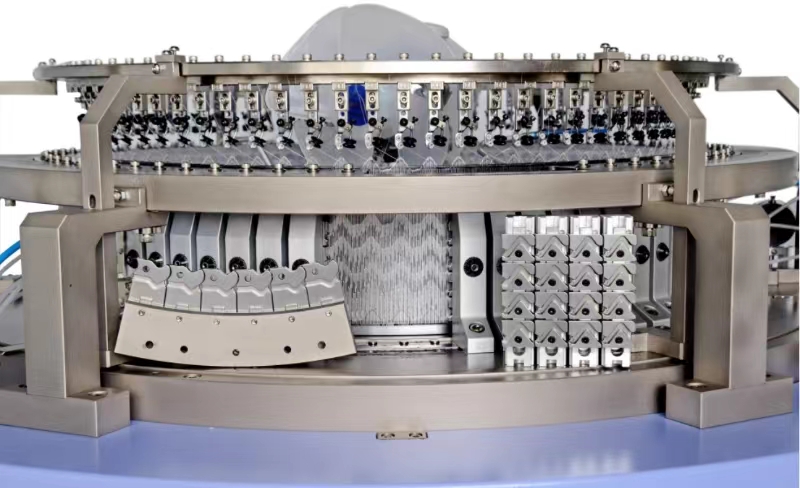

2. Knotisitionting Mechanism

Mokhoa oa ho li-mochine ke pelo ea mochini o potileng. E entsoe haholo kasilinda, li-khitting tsa khit, cam, setulo sa cam

3. Ho hula le moea o fokang

Ts'ebetso ea ho hula le ho fokotsa mochine oa ho hula le ho hula lesela le chabiseng ho tsoa sebakeng sa honopa le ho e sitisa foromo ea sephutheloana. Ho kenyelletsa ho hula, ho Rolling Roller, ho jala foreimi (hape ho bitsoa Fabric Rocker), letsoho la phetiso le ho fetola lebokose la 'mala. Litšobotsi tsa eona ke

(1) Ho na le switch ea kutlo e kentsoeng botlaaseng ba poleiti e kholo. Ha letsoho la phetiso le na le manase a tsamaeang le sesole sa cylindrical, sesupo se tla hlahisoa ho lekanya palo ea masela le palo ea litaba tsa phetoho.

(2) Beha palo ea liphetoho tsa lesela le leng le le leng la lesela ho phanele ea taolo. Ha palo ea liphetohelo tsa mochini o fihla boleng ba boima, e tla emisa ho laola phoso ea boima ba lesela ka har'a 0.5kg, e leng molemo ho ts'ebetso ea ho daela. Le silindar

(3) Phetohelo ea phetoho ea sebopeho sa rolling e ka aroloa ka tatellano ea litlhoko tsa masela a fapaneng ka mokhoa o fapaneng.

4.Convel

Mokhanni oa lebelo le tsoelang pele o laoloa ke 'maraka oa khafetsa, ebe koloi e khanna ka lehare la polelong e tšoanang, ka ho etsa joalo e ka khanna nalel ea ho matha. Shaft ea ho khanna e fetela ho mochini o chitja ka thipa ebe o khanna mochine oa ho fepa ka yarn.

5. Lubricte le mokhoa oa ho hloekisa

Mochine oa thipa o chitja ke lebelo le phahameng, e hokahane le e nepahetseng. Hobane u tla etsa hore palo e kholo ea litlolo tse fofang (li-lint) nakong ea ho loma, matheba le oli, a baka mathata a maholo. E tla senya lisebelisoa, ka hona, ho tlosoa ha likarolo tse tsamaeang ho bohlokoa haholo. Hona joale, liphallelo tsa mechine e chitja le litlolo tsa ho tlosa lerōle li kenyelletsa li-injectors tsa mafura, libapali tsa ho tlosa lerōle, lisebelisoa tsa potoloho ea oli, lisebelisoa tsa potoloho ea oli le likarolo tse ling.

Likarolo tsa mechini ea ho hloekisa le ho hloekisa

1. Mochine o khethehileng oa oli ea mafura o fana ka lubrication e ntle bakeng sa bokaholimo ba likarolo tse bohloko. Ho se supa le ho sebelisa mafura hoa mafura ho bonahala ka kotloloho. Ha bophahamo ba oli bo ka har'a mochini oa khang ea mafura ha bo natelle, bo tla koaloa ka bohona 'me bo lemosa.

2. Mochini o khathollang oa elektroniki o khathollang o etsa hore ho be le ho beha le ho buuoa le ho buuoa haholoanyane ebile ho hlaha.

3. Moratuoa oa Radar o na le sebaka se sephara 'me o ka tlosa li-flakes tse fofang ho tsoa sesebelisoa sa polokelo ho qoba phepelo e fuoeng e lekiloeng ea ho fofa.

6.Control Mechanism

Mokhoa o bonolo oa Ts'ebetso ea Ts'ebetso ea Konopo ea Ts'ebetso e sebelisoa ho phethela boemo ba liparamethara tse sebetsang, ho emisa ka ho ikenya le ho ba le matšoao a liphoso. Haholo-holo lihlatsi tsa khafetsa, li-panels tsa taolo (li-panels tse ngotsoeng pele), mabokose a taolo ea motlakase, thepa ea molato, monko oa motlakase, jj. Hape

7.Rack karolo

Karolo ea foreime e kenyelletsa maoto a mararo (e boetse e bitsoa maoto a ka holimo), maoto a otlolohileng (a boetse a bitsoa maoto a mararo, a sirelletsang le setulo sa tšepe. Ho hlokahala hore karolo ea racke e lokela ho tsitsa ebe e bolokehile.

Nako ea poso: Mar-09-2024